What is a Profile Meter?

A profile meter is a precision instrument used to measure the microscopic surface topography of objects. It can accurately depict the waviness, roughness, and macro-geometric shapes of a workpiece surface and provide quantitative values. The profile meter plays an irreplaceable role in ensuring product precision and consistency and has become an essential quality control tool in high-end fields such as automotive manufacturing, semiconductors, and aerospace.

The Working Process of a Profile Meter

Workpiece Fixation: Place the workpiece to be measured on the measuring platform, ensuring it is stable and free from vibration.

Instrument Calibration: Use standard gauge blocks or calibration samples for zero-point calibration.

Measurement Mode Selection:

Contact Mode: Adjust the probe pressure to avoid scratching the workpiece.

Non-contact Mode: Adjust the laser focus or optical parameters.

Contour Scanning: Move the probe or optical head along the set path to collect data.

Data Analysis: The software automatically calculates the contour deviation and generates a test report.

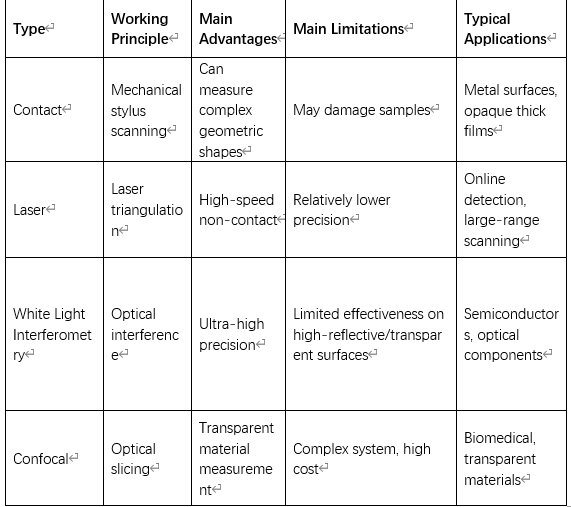

Main Types and Features of Profile Meters

Common profile meters are divided into two major categories: contact and non-contact profile meters.

Contact Profile Meter

Principle: It uses a high-precision probe (diamond or ruby) to contact the workpiece surface, records the displacement changes of the probe, and draws a contour curve.

Non-contact Profile Meter

Principle: It measures the contour using optical (laser, white light interferometry, confocal) or air-floating technology without contacting the workpiece.

How to Choose a Profile Meter?

When selecting a profile meter, the following factors need to be considered:

Measurement range (vertical and horizontal directions)

Resolution requirements

Characteristics of the material to be measured

Measurement environment (laboratory or production site)

Budget constraints

For enterprises and institutions considering introducing a profile meter, it is recommended to first clarify their own measurement needs, fully evaluate the characteristics of the samples and the working environment, and choose a system with matching technology and reasonable cost-effectiveness. At the same time, pay attention to the technical support and service capabilities of the supplier to ensure that the equipment can fully exert its efficiency. Proper selection will bring significant quality benefits and competitive advantages, and become a strong support for enterprise technological innovation and quality control.

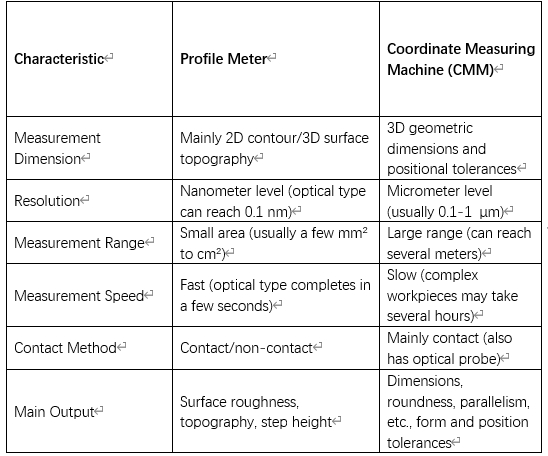

Profile Meter vs. Coordinate Measuring Machine (CMM)

Precautions

For contact measurement: The probe pressure needs to be moderate to avoid damaging the workpiece or the probe.

For non-contact measurement: Avoid strong light interference, and transparent/reflective surfaces may need to be sprayed with a developer.

Environmental Requirements: Anti-vibration, constant temperature (high-precision measurement requires an environment of 20±1℃).

Summary

With technological advancements, profile meters are becoming smarter, more efficient, and easier to use. One-click operation, automatic data analysis, and integration into production lines have greatly reduced the threshold for use. Innovations such as sub-nanometer resolution and multi-technology integration continue to expand the measurement limits. In the future, the introduction of artificial intelligence, cloud computing, and other technologies will further unleash the application potential of profile meters, making them play a more critical role in intelligent manufacturing and scientific research.

Ningbo Qianhao Metal Products Co., Ltd. is a professional casting and machining manufacturer. We have multiple profile meters that can meet the needs of different customers. Whether you are a first-time partner or a long-term collaborator, we will always provide you with high-quality products and services with 100% enthusiasm!

Author: Yanxiu Ji, Quality Manager